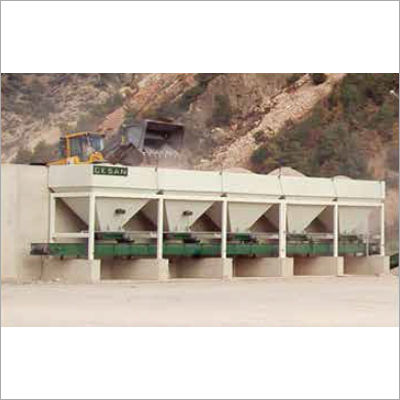

Cold Aggregate Bin Feeders and Conveyor Belts

Price 100000 INR/ Piece

Cold Aggregate Bin Feeders and Conveyor Belts Specification

- Hole Size

- Adjustable feeders up to 100 mm Meter (m)

- Driven Type

- Gear motor drive

- Noise Level

- 80 dB db

- Temperature

- -10 to +50C operating range Celsius (oC)

- Working Width

- 2200 mm belt width

- Mount Type

- Stationary (fixed) / Skid-mounted

- Hopper Capacity

- 10 m per bin Cubic Meter (m3)

- Coverage Area

- 12 m x 2.25 m Square Meter (m2)

- Fuel Type

- Electric

- Material

- Heavy-duty steel structure

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Vibration Frequency

- 50 Hz Hertz (HZ)

- Drum Diameter

- 600 mm Millimeter (mm)

- Power

- 5.5 kW (per conveyor) (varies by size) Watt (w)

- Size

- Standard and custom sizes

- Color

- Blue / Grey

- Weight

- Approx. 6,000 kg (entire unit) Kilograms (kg)

- Dimension (L*W*H)

- 12000 mm x 2250 mm x 3500 mm Millimeter (mm)

- Bin Gate Type

- Individually controlled pneumatically or manually

- Control Panel

- Weatherproof with operator-friendly interface

- Protection Class

- IP55 for electrical components

- Operating Personnel

- 1-2 operators

- Number of Bins

- 4 (can be customized up to 6)

- Finish

- Industrial-grade powder coating

- Conveyor Belt Material

- Heavy-duty rubber

- Belt Speed

- 0.5 to 2 m/s (adjustable)

- Feeder Adjustment

- Variable frequency drive (VFD) control

- Aggregate Size Range

- Up to 80 mm

- Assembly Time

- 1-2 days (site dependent)

- Discharge Height

- 3500 mm

- Loading Height

- 2800 mm

Cold Aggregate Bin Feeders and Conveyor Belts Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About Cold Aggregate Bin Feeders and Conveyor Belts

Cold Aggregate Bin Feeders and Conveyor Belts

High quality Cold Aggregate Bin Feeders offered by us that are ruggedly constructed and available in portable, skid mounted and modular configurations that offer a wide range of capacities depending on requirements. Feeders have an important function in belt conveying operations. Their function is to control the gravity flow of bulk solids from storage, such as from bins or stockpiles, and to provide a uniform feedrate to the receiving belt conveyor. The Cold Aggregate Bin Feeders offered by us for being used in the various applications. They are made for long term use under adverse conditions.

- Proven performance under harsh conditions.

- Frequency-Controlled sensitive dosing.

- Trouble-free flow.

- Vibrator for easy flow of fine material.

- Process can be controlled and followed from control cabin simultaneously Grid used to prevent passing of coarse material.

- Total proportional control for flexibility and accuracy.

FAQs of Cold Aggregate Bin Feeders and Conveyor Belts:

Q1. What are Cold Aggregate Bin Feeders used for?

Q2. What is the role of Conveyor Belts in an asphalt plant?

Q3. Why are Cold Aggregate Bin Feeders important?

Q4. What materials can be handled by these systems?

Q5. Can Cold Aggregate Bin Feeders and Conveyor Belts be customized?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Asphalt Drum Mix Plants Category

Asphalt Drum Mix Plants

Price 3000000 INR / Unit

Minimum Order Quantity : 1 Piece

Tank Dimensions (Mm X Mm X Mm) : 3500 x 2200 x 2200 mm

Working Width : Variable, up to 2.5 m

Dimension (L*W*H) : 11800 x 2600 x 3600 mm Millimeter (mm)

Compressor Type : Rotary air compressor

Soil Stabilization (Wet Mix Macadam) Plants

Price 1500000 INR / Piece

Minimum Order Quantity : 1 Piece

Tank Dimensions (Mm X Mm X Mm) : 3500 x 2200 x 2200 mm

Working Width : 2.5 3.5 meters

Dimension (L*W*H) : 14000 x 2800 x 4200 mm (Approx.) Millimeter (mm)

Compressor Type : Air Compressor Included

Concrete Batching Plant

Price 2500000 INR / Piece

Minimum Order Quantity : 1 Piece

Tank Dimensions (Mm X Mm X Mm) : 1200 x 1200 x 1500 mm

Working Width : 2500 mm

Dimension (L*W*H) : 7500 x 2500 x 8600 mm Millimeter (mm)

Compressor Type : Rotary

Automatic Asphalt Mixing Plant

Price 3650000 INR / Piece

Minimum Order Quantity : 1 Piece

Tank Dimensions (Mm X Mm X Mm) : 8000 x 3000 x 3000

Working Width : 3.8 m

Dimension (L*W*H) : 12,000 x 3,800 x 5,600 mm Millimeter (mm)

Compressor Type : Screw Type

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry