Asphalt Drum Mix Plants

Price 3000000 INR/ Unit

Asphalt Drum Mix Plants Specification

- Tank Dimensions (Mm X Mm X Mm)

- 3500 x 2200 x 2200 mm

- Driven Type

- Electric

- Air Pressure

- 7.5-8.5 kg/cm2 kgf/cm2

- Hopper Capacity

- 3 x 5.5 m3 Cubic Meter (m3)

- Coverage Area

- 800-1500 m2/h Square Meter (m2)

- Working Width

- Variable, up to 2.5 m

- Mount Type

- Stationary

- Temperature

- 100C - 180C Celsius (oC)

- Tank Material

- Mild Steel

- Fuel Type

- Diesel / Furnace Oil

- Noise Level

- Below 85 dB db

- Compressor Type

- Rotary air compressor

- Material

- Mild Steel

- Capacity

- 40-120 TPH T/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Vibration Frequency

- 50 Hz Hertz (HZ)

- Drum Diameter

- 1200-2500 mm Millimeter (mm)

- Power

- 100-160 HP Horsepower (HP)

- Size

- Standard

- Color

- Yellow & Black

- Weight

- Approx 25-32 Tonnes Kilograms (kg)

- Dimension (L*W*H)

- 11800 x 2600 x 3600 mm Millimeter (mm)

- Installation & Commissioning

- Available On Request

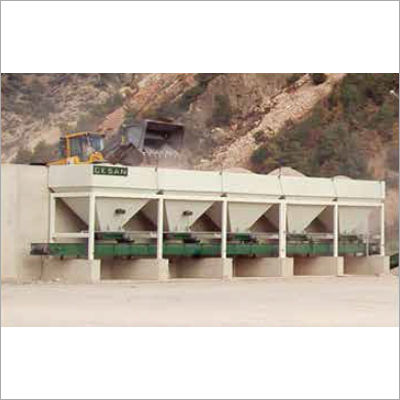

- Aggregate Feeding System

- Four Bin Type

- Conveyor Type

- Belt Conveyor with AC Drive

- Filler Unit

- Separate Filler Hopper with Screw Conveyor

- Control Panel

- Fully Automatic PLC Based

- Mixer Heating System

- Thermic Fluid / Oil Heating

- Bitumen Pump

- Positive Displacement Type

- Dust Collection System

- Multi Cyclone Type / Bag House

- Exhaust Fan

- High Capacity for Pollution Control

- Burner Type

- Auto Control Modulating Burner

- Chassis

- Heavy Duty Fabricated Frame

- Mobility

- Optional Tyre Mounted for Mobile Version

Asphalt Drum Mix Plants Trade Information

- Minimum Order Quantity

- 1 Piece

- FOB Port

- ahmedabad

- Payment Terms

- Cheque, Telegraphic Transfer (T/T), Western Union, Letter of Credit (L/C)

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 30 Days

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- Standard packaging

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- ISO

About Asphalt Drum Mix Plants

An asphalt drum mix plant, otherwise called a nonstop asphalt plant, is a kind of hot mix plant utilized for the consistent creation of asphalt mixture. It varies from cluster mix plants, which produce asphalt in discrete bunches. Asphalt drum mix plants are ordinarily utilized in enormous scope street development projects where a consistent stockpile of asphalt is required.

A few benefits of asphalt drum mix plants include:

- Nonstop activity: Asphalt drum mix plants give a persistent stockpile of asphalt mixture, taking into consideration effective and continuous creation.

- Higher creation rates: These plants can accomplish higher creation rates contrasted with clump mix plants.

- Predictable quality: The nonstop mixing process guarantees a steady and uniform mixture, bringing about great asphalt.

- Lower energy utilization: The drum mix configuration takes into consideration better intensity move and lower energy utilization contrasted with other plant types.

- Simple support: Asphalt drum mix plants are by and large more straightforward to keep up with because of their less difficult plan and less moving parts.

THERMO DRUM UNIT

The Drying and Mixing unit of the asphalt plant demands complex flight design and heat transfer technology. With our passion to build the best machines, continuous R & D and incorporation of the latest design up-gradations, KEW thermo drum is way ahead of competition.

The KEW thermo drum unit follows a triple heat transfer system that ensures a total transfer of heat to the aggregates, translating into higher productivity and lower fuel consumption. The heat is transferred to the aggregates using the conductive, connective and radiation techniques.

The field proven unique flight design ensures total heat transfer, a thorough mixing & coating, lower emissions and prevention of bitumen oxidation.

DRUM MECHANICS

The 30-12oTph plants are supplied with a low maintenance cradle type drum drive. The auto lubrication system ensures proper and adequate lubrication on the chain drive thereby ensuring long life of machine with trouble free service. Optionally a four wheel friction drive, which is a standard on the 120 Tph and higher models, can be supplied.

Specially treated sprockets, thrust wheels, trunion rings & trunion rollers, engineered precisely for flawless and trouble free dryer drum rotation, ensures unlimited productivity.

|

|

KEW 45 (45-60 TPH) |

KEW 50 (60-90 TPH) |

KEW 60 (90-120 TPH) |

KEW 65 (90-120 TPH) |

|

Four bin feeder |

|

|

|

|

|

No of bins |

4 |

4 |

4 |

4 |

|

Storage capacity |

31 MT |

40 MT |

54 MT |

54 MT |

|

Hopper size (lxw) |

2500mmx2200mm |

3000mmx2200mm |

3650mmx2060mm |

3650mmx2060mm |

|

Auxllary drive motor |

1.1 kw x 4 Nos |

1.5 kw x 4 Nos |

2.2 kw x 4 Nos |

2.2 kw x 4 Nos |

|

Auxllary conveyor belt |

400mm x 2.2 mtr |

450mm x 2.92mtr |

450mm x 3.78mtr |

450mm x 3.78mtr |

|

Gathering drive motor |

3.70 kw |

3.70 kw |

5.50 kw |

5.50 kw |

|

Gathering conveyor belt |

500mm x 22.5 mtr |

600mm x 25.6 mtr |

600mm x 29.6 mtr |

600mm x 29.6 mtr |

|

Bin virbrator (1 No) |

0.75 kw |

0.75 kw |

0.75 kw |

0.75 kw |

|

Feeding capacity |

100 TPH |

150 TPH |

200 TPH |

200 TPH |

|

Overall dimension (approx) |

11.6 mtr x2.55mtr x 2.45 |

13.5 mtr x 2.55 mtr x 2.45 mtr |

16.25 mtr x 2.55 mtr x 2.75 mtr |

16.25 mtr x 2.55 mtr x 3.00 mtr |

|

Total connected load |

8.85 kw |

10.45 kw |

15.05 kw |

15.5 kw |

|

Over size removal screen |

||||

|

Diver motor |

0.75 kw |

0.75 kw |

0.75 kw |

0.75 kw |

|

Wire mesh |

45mm x 45mm |

45mm x 45mm |

45mm x 45mm |

45mm x 45mm |

|

Screening belt |

800 x 1200 mm |

800 x 1200 mm |

900 x 1200 mm |

900 x 1200 mm |

|

Silnger converyor |

||||

|

Conveyor drive motor |

2.20 kw |

3.70 kw |

3.70 kw |

3.70 kw |

|

Conveyor belt |

500mm x 15 mtr |

600mm x 15 mtr |

600mm x 15 mtr |

600mm x 15 mtr |

Specification of Asphalt Drum Mix Plant:

|

Brand |

Kaushik |

|

Capacity |

150 TPH |

|

Usage/Application |

Construction |

|

Pump Power |

175 Hp |

|

Country of Origin |

Made in India |

|

Is It Portable |

Non Portable |

|

Material |

Mild Steel |

|

Automatic Grade |

Automatic |

FAQs of Asphalt Drum Mix Plant:

Q. How does an asphalt drum mix plant work?

A. In an asphalt drum mix plant, totals are taken care of into a revo lving drum alongside an exact measure of bitumen. The totals are warmed and dried as they go through the drum, while being mixed with the hot bitumen. The subsequent asphalt mixture is then released ceaselessly from the drum and put away in a capacity storehouse or stacked straightforwardly into trucks for transportation.

Q. Could various kinds of asphalt mixtures at any point be created in an asphalt drum mix plant?

A. Indeed, asphalt drum mix plants can deliver different kinds of asphalt mixtures, including various degrees and asphalt fastener types. By changing the extent of totals and bitumen, the plant can create mixtures reasonable for different street development projects.

Q. How are emanations and ecological effect oversaw in asphalt drum mix plants?

A. Like other asphalt plants, asphalt drum mix plants are furnished with contamination control gadgets, for example, baghouses or wet scrubbers, to catch and control outflows of particulate matter and vaporous poisons. These gadgets assist with limiting the ecological effect of plant activities. Also, adherence to neighborhood ecological guidelines and best practices is essential to guarantee mindful and supportable activity of asphalt drum mix plants.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Asphalt Drum Mix Plants Category

Soil Stabilization (Wet Mix Macadam) Plants

Price 1500000 INR / Piece

Minimum Order Quantity : 1 Piece

Noise Level : < 85 dB db

Fuel Type : Diesel / Electric

Dimension (L*W*H) : 14000 x 2800 x 4200 mm (Approx.) Millimeter (mm)

Automatic Grade : Automatic

Asphalt Drum Mixing Plant

Price 4499999 INR / Piece

Minimum Order Quantity : 1 Piece

Noise Level : Below 85 dB db

Fuel Type : Diesel

Dimension (L*W*H) : 13460 x 2250 x 4030 mm Millimeter (mm)

Automatic Grade : Automatic

Asphalt Mix Plant

Price 2500000 INR / Piece

Minimum Order Quantity : 1 Piece

Noise Level : 85 dB db

Fuel Type : Diesel/Electric

Dimension (L*W*H) : 16000 x 2500 x 4000 mm Millimeter (mm)

Automatic Grade : Automatic

Cold Aggregate Bin Feeders and Conveyor Belts

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Noise Level : 80 dB db

Fuel Type : Electric

Dimension (L*W*H) : 12000 mm x 2250 mm x 3500 mm Millimeter (mm)

Automatic Grade : SemiAutomatic

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free