Asphalt Drum Mix Plant

Price 2500000 INR/ Piece

Asphalt Drum Mix Plant Specification

- Fuel Type

- Diesel

- Type

- Asphalt Mixers

- Material

- Mild Steel

- Capacity

- 120 T/hr

- Computerized

- No

- Automatic Grade

- Automatic

- Cooling System

- Human Machine Interface

- Vibration Frequency

- 50 Hertz (HZ)

- Power

- 175 Horsepower (HP)

- Size

- Standard

- Color

- Yellow & silver

- Warranty

- 1 Year

Asphalt Drum Mix Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Asphalt Drum Mix Plant

An Asphalt Drum Mix Plant is a continuous asphalt production system designed to mix aggregates, bitumen, and fillers in a single rotating drum to produce hot mix asphalt efficiently. It is widely used in large-scale road construction projects due to its high output, lower operating costs, and consistent mixing quality. With advanced burner technology and robust construction, Asphalt Drum Mix Plants ensure uniform heating, reduced fuel consumption, and reliable performance, making them ideal for highways, expressways, and infrastructure development projects.

Specification of Asphalt Drum Mix Plant:

|

Brand |

Kaushik |

|

Capacity |

150 TPH |

|

Usage/Application |

Construction |

|

Pump Power |

175 Hp |

|

Country of Origin |

Made in India |

|

Is It Portable |

Non Portable |

|

Material |

Mild Steel |

|

Automatic Grade |

Automatic |

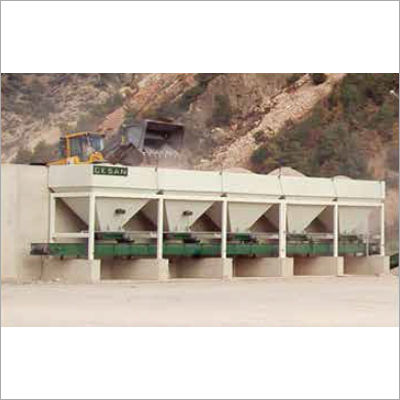

THERMO DRUM UNIT

DRUM MECHANICS

The 30-12oTph plants are supplied with a low maintenance cradle type drum drive. The auto lubrication system ensures proper and adequate lubrication on the chain drive thereby ensuring long life of machine with trouble free service. Optionally a four wheel friction drive, which is a standard on the 120 Tph and higher models, can be supplied.

Specially treated sprockets, thrust wheels, trunion rings & trunion rollers, engineered precisely for flawless and trouble free dryer drum rotation, ensures unlimited productivity.

|

|

KEW 45 (45-60 TPH) |

KEW 50 (60-90 TPH) |

KEW 60 (90-120 TPH) |

KEW 65 (90-120 TPH) |

|

Four bin feeder |

|

|

|

|

|

No of bins |

4 |

4 |

4 |

4 |

|

Storage capacity |

31 MT |

40 MT |

54 MT |

54 MT |

|

Hopper size (lxw) |

2500mmx2200mm |

3000mmx2200mm |

3650mmx2060mm |

3650mmx2060mm |

|

Auxllary drive motor |

1.1 kw x 4 Nos |

1.5 kw x 4 Nos |

2.2 kw x 4 Nos |

2.2 kw x 4 Nos |

|

Auxllary conveyor belt |

400mm x 2.2 mtr |

450mm x 2.92mtr |

450mm x 3.78mtr |

450mm x 3.78mtr |

|

Gathering drive motor |

3.70 kw |

3.70 kw |

5.50 kw |

5.50 kw |

|

Gathering conveyor belt |

500mm x 22.5 mtr |

600mm x 25.6 mtr |

600mm x 29.6 mtr |

600mm x 29.6 mtr |

|

Bin virbrator (1 No) |

0.75 kw |

0.75 kw |

0.75 kw |

0.75 kw |

|

Feeding capacity |

100 TPH |

150 TPH |

200 TPH |

200 TPH |

|

Overall dimension (approx) |

11.6 mtr x2.55mtr x 2.45 |

13.5 mtr x 2.55 mtr x 2.45 mtr |

16.25 mtr x 2.55 mtr x 2.75 mtr |

16.25 mtr x 2.55 mtr x 3.00 mtr |

|

Total connected load |

8.85 kw |

10.45 kw |

15.05 kw |

15.5 kw |

|

Over size removal screen |

||||

|

Diver motor |

0.75 kw |

0.75 kw |

0.75 kw |

0.75 kw |

|

Wire mesh |

45mm x 45mm |

45mm x 45mm |

45mm x 45mm |

45mm x 45mm |

|

Screening belt |

800 x 1200 mm |

800 x 1200 mm |

900 x 1200 mm |

900 x 1200 mm |

|

Silnger converyor |

||||

|

Conveyor drive motor |

2.20 kw |

3.70 kw |

3.70 kw |

3.70 kw |

|

Conveyor belt |

500mm x 15 mtr |

600mm x 15 mtr |

600mm x 15 mtr |

600mm x 15 mtr |

FAQs of Asphalt Drum Mix Plant:-

Q1. What is an Asphalt Drum Mix Plant?

An Asphalt Drum Mix Plant is a continuous mixing plant that produces hot mix asphalt by combining aggregates and bitumen inside a rotating drum.

Q2. How is a Drum Mix Plant different from a Batch Mix Plant?

A Drum Mix Plant works continuously, while a Batch Mix Plant produces asphalt in fixed batches, making drum plants more suitable for high-volume production.

Q3. Where are Asphalt Drum Mix Plants commonly used?

They are mainly used in highways, expressways, airport runways, and large road construction projects.

Q4. What are the advantages of using an Asphalt Drum Mix Plant?

It offers high production capacity, low fuel consumption, uniform mixing, and reduced operational costs.

Q5. Can an Asphalt Drum Mix Plant be customized?

Yes, it can be customized based on output capacity, fuel type, control system, and project-specific requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Asphalt Drum Mix Plants Category

Asphalt Drum Mixing Plant

Price 4499999 INR / Piece

Minimum Order Quantity : 1 Piece

Driven Type : Electric

Computerized : Yes

Dimension (L*W*H) : 13460 x 2250 x 4030 mm Millimeter (mm)

Fuel Type : Diesel

Concrete Batching Plant

Price 2500000 INR / Piece

Minimum Order Quantity : 1 Piece

Driven Type : Electric

Computerized : Yes

Dimension (L*W*H) : 7500 x 2500 x 8600 mm Millimeter (mm)

Fuel Type : Electric

Cold Aggregate Bin Feeders and Conveyor Belts

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Driven Type : Gear motor drive

Computerized : No

Dimension (L*W*H) : 12000 mm x 2250 mm x 3500 mm Millimeter (mm)

Fuel Type : Electric

Mixer Blend

Price 100000 INR / Unit

Minimum Order Quantity : 1 Piece

Driven Type : Electric

Computerized : No

Dimension (L*W*H) : 1200 x 800 x 1000 mm Millimeter (mm)

Fuel Type : Electric

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free