Asphalt Batch Mix Plant

Price 16500000 INR/ Piece

Asphalt Batch Mix Plant Specification

- Fuel Type

- Electric

- Working Width

- Up to 1800 mm

- Mount Type

- Floor Mounted

- Hole Size

- 2-10 mm Millimeter (mm)

- Driven Type

- Electric

- Hopper Capacity

- 200-500 kg Kilogram(Kg)

- Coverage Area

- Up to 120 m Square Meter (m2)

- Material

- Stainless Steel

- Capacity

- 1-20 TPH T/hr

- Computerized

- No

- Automatic Grade

- Automatic

- Vibration Frequency

- 50 Hz Hertz (HZ)

- Drum Diameter

- 600-1800 mm Millimeter (mm)

- Power

- 2-10 HP Horsepower (HP)

- Size

- Customizable

- Color

- Grey

- Weight

- 500-2000 kg Kilograms (kg)

- Application

- Industrial, Mining, Aggregate, Chemical Processing

- Motor Brand

- Standard/ABB/Siemens

- Installation Service

- Available

- Voltage

- 220-440V

- Maintenance

- Low Maintenance

- Screen Deck

- Single/Double/Triple

- Mesh Material

- High Tensile Steel/Polyurethane

Asphalt Batch Mix Plant Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Day

- Delivery Time

- 1 Days

About Asphalt Batch Mix Plant

An Asphalt Batch Mix Plant is a high-performance road construction machine used to produce hot mix asphalt by precisely mixing heated aggregates, bitumen, and fillers in controlled batches. It ensures superior quality, uniform composition, and consistent output, making it ideal for highways, city roads, airports, and large infrastructure projects. Designed with advanced technology and robust components, Asphalt Batch Mix Plants offer high efficiency, low fuel consumption, and reliable operation, helping contractors achieve durable, smooth, and long-lasting asphalt pavements.

Specifications of Asphalt Batch Mix Plant:-

- Optional 4/5/6 horizontal decks

- Driving is done by vibrator or eccentric weight system

- Tension, Perfect inclination and homogeneous load distribution provide trouble-free capacity

- Perfect inner design that prevents the mixing of different sizes of materials

- Easy changeable sieves, useful doors platforms

- It can be used as by-pass by means of 0-5 compartment of sieving machine

FAQs of Asphalt Batch Mix Plant:-

Q1. What is an Asphalt Batch Mix Plant?

Q2. What are the main applications of an Asphalt Batch Mix Plant?

Q3. What are the benefits of using an Asphalt Batch Mix Plant?

Q4. What type of fuel does an Asphalt Batch Mix Plant use?

Q5. Can an Asphalt Batch Mix Plant be customized?

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Asphalt Drum Mix Plants Category

Asphalt Drum Mixing Plant

Price 4499999 INR / Piece

Minimum Order Quantity : 1 Piece

Driven Type : Electric

Hopper Capacity : 1200 kg Kilogram(Kg)

Material : Mild Steel, Stainless Steel

Dimension (L*W*H) : 13460 x 2250 x 4030 mm Millimeter (mm)

Concrete Batching Plant

Price 2500000 INR / Piece

Minimum Order Quantity : 1 Piece

Driven Type : Electric

Hopper Capacity : 1000 L Liter (L)

Material : Mild Steel

Dimension (L*W*H) : 7500 x 2500 x 8600 mm Millimeter (mm)

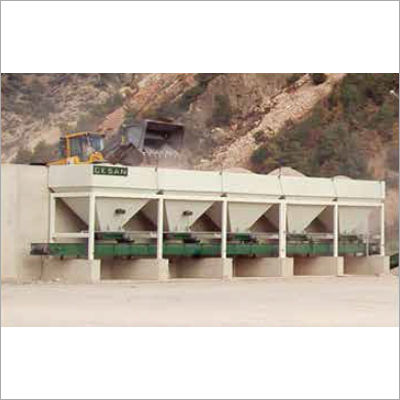

Cold Aggregate Bin Feeders and Conveyor Belts

Price 100000 INR / Piece

Minimum Order Quantity : 1 Piece

Driven Type : Gear motor drive

Hopper Capacity : 10 m per bin Cubic Meter (m3)

Material : Heavyduty steel structure

Dimension (L*W*H) : 12000 mm x 2250 mm x 3500 mm Millimeter (mm)

Mixer Blend

Price 100000 INR / Unit

Minimum Order Quantity : 1 Piece

Driven Type : Electric

Hopper Capacity : 50 kg Kilogram(Kg)

Material : Stainless Steel

Dimension (L*W*H) : 1200 x 800 x 1000 mm Millimeter (mm)

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese Send Inquiry

Send Inquiry