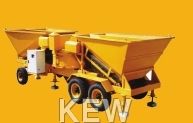

Mobile Concrete Batching Plant

1500000 INR/Piece

Product Details:

- Product Type Mobile Concrete Batching Plant

- General Use Concrete Mixing and Batching for Construction Sites

- Material Mild Steel Structure with Heavy Duty Components

- Computerized Yes

- Power Source Electric

- Power Consumption 15 kW 30 kW (depending on capacity) Kilowatt (kW)

- Hopper Capacity 1200 Ltr to 2000 Ltr (per batch) Liter (L)

- Click to view more

X

Mobile Concrete Batching Plant Price And Quantity

- 1500000 INR/Piece

- 1 Piece

Mobile Concrete Batching Plant Product Specifications

- Mild Steel Structure with Heavy Duty Components

- 415 V, 3 Phase, 50 Hz Volt (v)

- Other

- 9000 mm x 2400 mm x 3700 mm (approx.) Millimeter (mm)

- Yes

- Electric

- Mobile Concrete Batching Plant

- 1200 Ltr to 2000 Ltr (per batch) Liter (L)

- Concrete Mixing and Batching for Construction Sites

- 15 kW 30 kW (depending on capacity) Kilowatt (kW)

- Industrial Yellow / Customizable

- 3 or 4 Bins (Aggregate Hoppers) Pieces

Mobile Concrete Batching Plant Trade Information

- 11 Piece Per Week

Product Description

Backed by the team of talented professionals, we are engaged in manufacturing, exporting and supplying Mobile Concrete Batching Plant. The plant is manufactured under the visionary guidance of talented professionals at our well-equipped premises. Widely demanded in heavy duty construction and related industries to process large amount of concrete, the provided batching plant finds application in road construction industries. Besides, the provided Mobile Concrete Batching Plant can be purchased at reasonable prices from us.

Features:

Features:

- Smooth operations and weather proof construction

- Power efficient

- Longer life

- Easy to use

Specifications:

|

Model |

KEW-MC15 |

KEW-MC20 |

|

Capacity |

15 m3/hr |

20 m3/hr |

Specification of Mobile Concrete Batching Plant:

|

Power Source |

Diesel |

|

Automation Grade |

Semi-Automatic |

|

Brand |

Kaushik |

|

Output Capacity |

Cu m3/hr |

|

Type Of The Drum Mixer |

Tilting Drum Mixer |

|

Motor Power |

40 Hp |

|

Country of Origin |

Made in India |

|

Floor Space Required |

3X4 Ft |

Efficient and Versatile Concrete Production

This mobile concrete plant combines advanced batching technology with mobility for hassle-free transportation and rapid setup at project sites. Its computer-controlled operation ensures accuracy in every batch, supported by highly reliable weighing systems, automatic admixture dosing, and safety interlocks. Capable of handling demanding project needs, it delivers high-quality concrete efficiently.

User-Friendly Operation and Rapid Setup

Engineered for minimal foundation requirements, this plant enables installation and commissioning within a single day. An intuitive PLC-based control system streamlines operation, providing full automation with manual override options if needed. The clear HMI display enh ances user experience, monitoring all vital parameters for smooth batching and mixing processes.

Safety, Durability, and Customization

Safety is prioritized through features like emergency stops, overload protection, and smart interlocks. Built from heavy-duty, durable materials, the mobile batching plant is designed for extended life and rigorous site conditions. Customize the color and capacity to meet specific project or branding requirements. Low noise operation ensures compliance with site regulations.

FAQs of Mobile Concrete Batching Plant:

Q: How quickly can the mobile concrete batching plant be installed at a construction site?

A: The plant is designed for rapid deployment, allowing installation and commissioning to be completed in less than one day, thanks to its minimal foundation requirements and user-friendly setup process.Q: What types of mixers are available with this mobile batching plant?

A: You can select from Twin Shaft, Pan, or Reversible Drum mixers. Each mixer type offers distinct benefits for concrete consistency and is suitable for a range of construction applications, ensuring flexibility in use based on project needs.Q: What is the process for weighing aggregates and cement in this plant?

A: Both aggregates and cement are measured using digital load cell-based weighing systems. This computerized approach ensures precise and reliable dosing of materials for every batch, enh ancing quality control in concrete production.Q: Where can this mobile concrete batching plant be effectively utilized?

A: This plant is ideal for diverse construction sitesincluding urban, remote, and infrastructure projectswhere mobility, fast setup, and consistent concrete supply are essential priorities.Q: What are the primary safety features incorporated in this batching plant?

A: Safety is ensured through integrated emergency stop buttons, overload protection systems, and interlocks on critical operations. These features reduce the risk of accidents and protect both operators and equipment.Q: What are the benefits of using a PLC-based control system with HMI display?

A: The PLC-based system with HMI display facilitates streamlined operation, real-time monitoring, and easy adjustment of parameters. It boosts efficiency, reduces error, and allows for fully automatic functioning with an option for manual control if necessary.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese