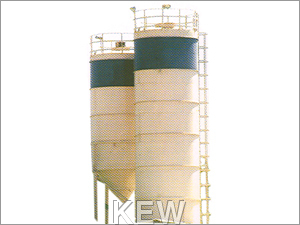

Cement Silo System

Cement Silo System Specification

- Product Type

- Vertical Storage Silo

- Material

- Mild Steel

- Finish

- Paint Coated

- Color

- Grey

- Bottom Type

- Conical

- Power

- 7.5 kW Watt (w)

- Voltage

- 380 V Volt (v)

- Usage

- Industrial Cement Storage

Cement Silo System Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Week

- Delivery Time

- 1 Week

About Cement Silo System

We are a trustworthy entity entity, successfully engaged in manufacturing, exporting and supplying the best quality Cement Silo System. The offered system is manufactured under the supervision of ingenious professionals as per industry standards. Widely used for storage of cement in large amount, this is checked by quality professionals on several aspects to ensure its flawlessness. Moreover, the provided Cement Silo System can be purchased at economic prices from us.

Key points of Cement Silo System:

- Based on advanced techniques

- Longer service life

- Excellent efficiency

- Low power consumption

Technical Specification

|

Model |

KEW-S25 |

KEW-S50 |

KEW-S60 |

KEW-S100 |

|

Capacity |

25 Ton |

50 Ton |

60 Ton |

100 ton |

FAQs of Cement Silo System:

Q: How does the pneumatic and manual discharge system work in this cement silo?

A: The system offers two discharge methods: pneumatic discharge uses pressurized air to move cement out of the silo efficiently, while manual discharge allows for straightforward hand-operated release as required. This ensures flexibility and adaptability to various operational needs.Q: What safety and monitoring features are included with the cement silo system?

A: The silo is equipped with level sensors for accurate inventory monitoring and a pressure relief valve to prevent over-pressurization. Additionally, it features a manhole for safe access and a ladder with a guardrail to maximize worker safety during inspection or maintenance.Q: When should maintenance and cleaning be carried out on this silo?

A: Thanks to its low-maintenance design and easy access ports, routine checks and cleaning can be performed as part of regular industrial maintenance schedulestypically once per cycle or as recommended based on usage and environmental conditions.Q: Where is this cement silo system best installed?

A: Ideal for industrial settings, the silo system mounts securely using a bolted steel base plate on solid ground. Custom dimensions allow it to fit various plant layouts, making it suitable for cement storage facilities across India and diverse global projects.Q: What is the process for inspecting and cleaning the silo?

A: Inspection is simplified via dedicated cleaning and inspection ports, along with the service manhole. Operators can safely access the interior for debris removal or component checks without extensive system downtime, keeping discharges efficient and the material uncontaminated.Q: How does this silos design benefit industrial cement storage operations?

A: The robust, humidity-resistant mild steel structure ensures durability, while the conical bottom and 60-degree hopper minimize residue. Reliable level sensors, easy access, and low maintenance needs translate into increased uptime, improved safety, and operational efficiency for your facility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cement Silo Category

Hot Mix Silo

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Piece

Voltage : 380 V Volt (v)

Finish : Other, Paint Coated

Capability : Continuous Operation

Usage : Storage of hot mix asphalt

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free